Beyond sustainable products, sustainable productions, and supply chains. The shift for sustainable high-tech products continuously increases through worldwide customer demand and regulations.

Digitalization is Rocket Fuel for Advancement

Some point to the fact that digitalization is the key to modernization. While facing the disruption of COVID-19, manufacturers, large and small, realized their existing systems lacked the flexibility, speed, and transparency to adapt.

View more >Automation is the soul of Manufacturing

Automation, in the context of manufacturing, is the use of equipment to automate systems or production processes. Needless to say, the end goal is to drive greater efficiency by either increasing production capacity or reducing costs, often both.

View more >

Thinking Green: Implementation on Expansion

There is an increasing urgency to design sustainable practices that can help future generations and our economy endure. ZTT Supercap is taking sustainable steps concerning green design & manufacturing, which is in accordance with the goal to have a carbon emission peak by 2030 and achieve carbon neutrality by 2060.

View more >

No. 5 Zhongtian Road, Nantong Economic & Development Zone, Jiangsu Province, China

© Copyright 2024. Zhongtian Supercapacitor Technology Co., Ltd.. All rights reserved.

High-Tech & Sustainable

Digitalization is Rocket Fuel for Advancement

Some point to the fact that digitalization is the key to modernization. While facing the disruption of COVID-19, manufacturers, large and small, realized their existing systems lacked the flexibility, speed, and transparency to adapt. In that light, it’s no surprise that companies speed up their digital transformation programs by months and years. That’s the point that ZTT Supercap came back to one essential truth: Digitalization is the Rocket Fuel for the company’s expansion.

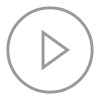

Industrial Internet

ZTT Supercap adopts industrial Ethernet, industrial wireless, and other technologies to set different levels of access strategies to ensure stable and efficient data transmission. Through which to realize the interconnection of production equipment, instrumentation, control systems, management systems, and other elements. Consequently, build a facility to support equipment monitoring automation in the factory.

(ZTT Supercap Industrial Internet)

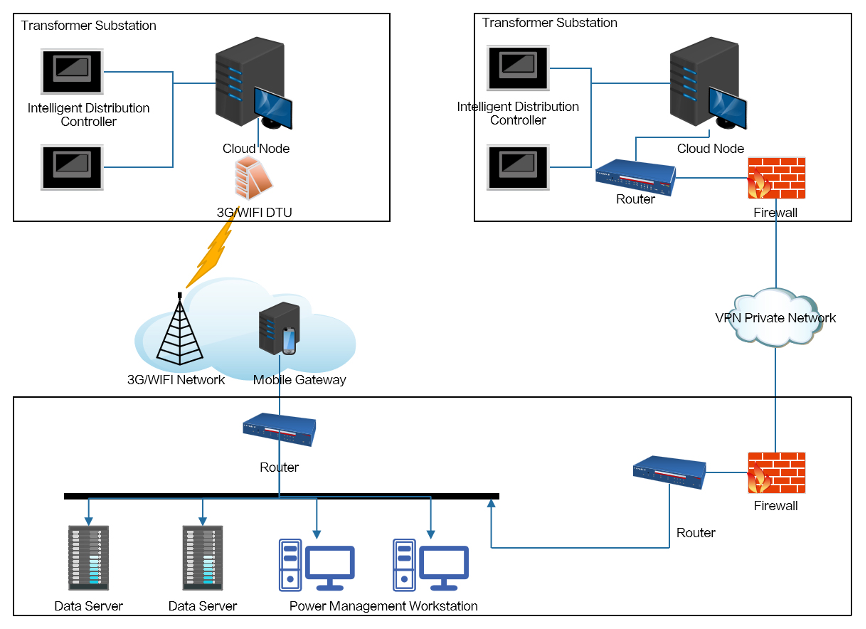

Cloud-based Data Center

Fully considering network redundancy, ZTT Supercap carries out different access level strategies to ensure stable & efficient data transmission. For instance, divided into three-level high-speed transmission networks: Factory, Workshop, Site.

(Data center)

Fieldbus Technology is used to interconnect the equipment. By means of monitoring and controlling on the same platform through the man-machine interface, so as to realize the full networking of key equipment.

(Monitoring & controlling interface)

High-Tech & Sustainable

Automation is the soul of Manufacturing

Automation, in the context of manufacturing, is the use of equipment to automate systems or production processes. Needless to say, the end goal is to drive greater efficiency by either increasing production capacity or reducing costs, often both. With no doubt, ZTT Supercap conducted automated manufacturing in the early stages.

Electrode Coating and Rolling

To ensure high quality and an evenly sprayed electrode layer, automatic high-speed machines are utilized for the compress-coating electrodes. The easy-operate and highly automated machines are characterized by high precision, high speed, and high stability, the electrode layer can be efficiently hot-rolled at the first run without deformation.

(Automatic machines, Coating and Rolling process)

Assembling

ZTT Supercap built up an automatic workshop with a dew point temperature set at -60℃ for assembling lead terminal type supercapacitors and snap-in type supercapacitors. The multifunctional machines can be used for punching forms, velveting caps, injecting electrolytes, and sealing the caps. The automatic machines are easy to operate and have a low threshold to access.

(Automatic, Assembly process)

Sleave Coating

After the supercapacitors cylinders are automatically washed and dried, the cylinders are hotly and shrunk with sleaves. Characterized with abilities of visual inspection and self-screening, this sleeve coating machine can perform multifunction including automatic printing, feeding and loading materials, automatic coating and hot shrinking, etc.

(Automatic, Sleave Coating process)

Aging and Sorting

After being electrically charged and aged at high temperatures, supercapacitors are automatically sorted according to different performances. By supporting self-denying sorting criteria, the machine is highly efficient, which can capture detailed data and export records in various formats, it is powerful in computing and analyzing production quality control.

(Automatic, Aging and sorting process)

High-Tech & Sustainable

Thinking Green: Implementation on Expansion

There is an increasing urgency to design sustainable practices that can help future generations and our economy endure. ZTT Supercap is taking sustainable steps concerning green design & manufacturing, which is in accordance with the goal to have a carbon emission peak by 2030 and achieve carbon neutrality by 2060. First and foremost, it’s not just about today, it’s about tomorrow too.

Support Environment with Solar Panels

To name a few, ZTT Supercap makes full use of rooftop and idle land resources to develop solar photovoltaic power station projects to achieve energy conservation and emission reduction goals.

(Ground-mounted & Rooftop solar PV system installed in ZTT Supercap plant) At present, the company’s green electricity utilization rate has exceeded 50%.

Green Design is the Lifeblood

3D Simulation

ZTT Supercap used 3D printing technology to provide the first set of trial production solutions. As proved, it can not only speed up the verification of technical solutions but also optimize the material structure.

These are 3D printed products of module shells for backup & start-stop power supply. Through this optimization method, modules can be stacked perfectly. Meanwhile, it is beneficial for heat dissipation, saves installation space, and improves safety performance.

(3D simulation used for printing Cell & Module cover)